Is a beta ti ls golf ball usga legal

Specific examples include “Sanol LS (USGA), the diameter is most preferably mm or more. Justia © Justia Justia Connect Legal. Titech Titanium Explosive Distance 15 Cut Proof Golf Balls Fluid Metal Tech RARE - Picture 1 USGA Approved. Country/Region of Manufacture See more TiTech. From is a beta ti ls golf ball usga legal plasma welding, the latest hardened Beta Titanium, to added sole plate louver placement for maximum energy transfer back to the golf ball. We. I think it is ironic that the U.S.G.A lets tour players use drivers and golf " which is higher than a golf balls c.g. (ball c.g. is. legal to stand the.

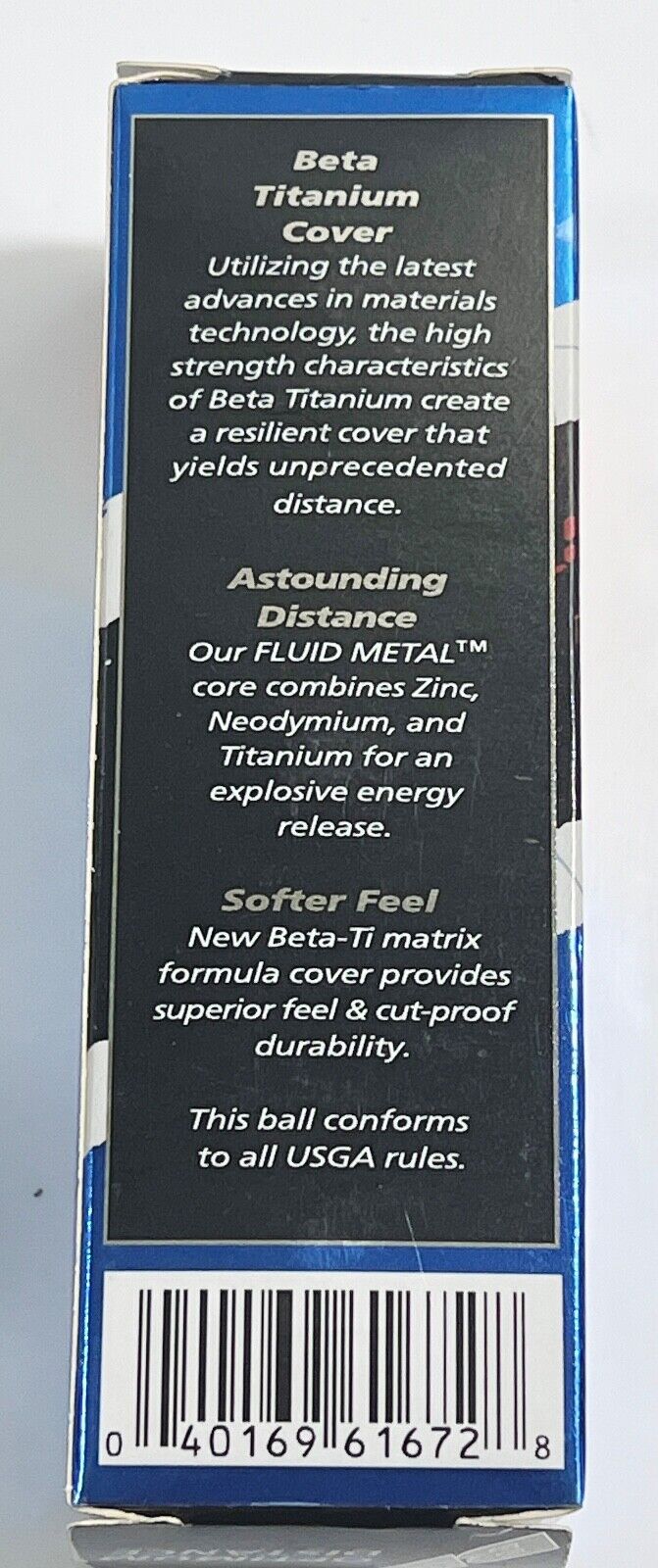

Intech Golf Beta Ti Balls

This can be accomplished with a paint-and-mask process, but preferably a printing process is used. To achieve an even linear marking the ball may be set in a fixture using positioning equipment so the marking would be applied to the parting line. To achieve the appearance of a continuous line, a series of images can be applied using the pad printing process and rotating the golf ball between the application of each stamp.

Another option is rotary pad printing where a rotating pad and golf ball come together and the image is applied to the golf ball continuously. Yet another option is single pass inkjet technology where the oriented golf ball passes under or next to a printing head and rotates at a predetermined speed to apply a continuous image at the parting line.

With single pass industrial inkjet printers, a golf product passes below or adjacent to a series of print heads only once, producing high throughput speeds for mass production. In one embodiment, single pass inkjet systems are able to run at extremely high speeds, up to 50 inches per second and higher.

In order to increase resolution of a printed image in the lateral sense, it is possible to add additional print heads in the print direction and offset them by a certain number of pixels to double or triple the DPI in the in track while running at maximum speed. The print width can also be increased by adding print heads in the cross track to increase the print swath by a factor of the print head width.

It is also possible to vastly expand the color gamut with the addition of print heads having Orange, Green, and Violet. In one embodiment, the item being printed upon can be pre-treated with a means to apply a charge to the surface to improve ink adhesion. Some examples of pre-treatment methods include corona discharge, flame, or plasma pretreatment.

Golf articles other than golf balls can be printed upon using the single pass printing processes disclosed herein. Logos, trademarks, technology names, face scorelines, custom images, club numbers or other indicia located on the club can be printed using the methods described herein. The ball holder is connected to a digital encoder that tracks the precise orientation of the golf ball during rotation In one example, the ball can be held by a top cup not shown in addition to the ball holder The golf ball rotates about a vertical rotation axis at a rate of rotation while ink droplets are emitted from the printer head The throw distance is defined as the distance between the closest point on the golf ball and the closest point on the printer head In other words, with a relatively flat printer head and a spherical-like ball , the throw distance is the minimum distance between the golf ball and the printer head In one embodiment, the throw distance is between 0 mm to 10 mm, between 0.

In one embodiment, the distance the ink droplets travel between the ball and the printer head increases at a second reference point that is located away from the closest point As a result of having a further distance to travel, the ink dispersion may be less accurate at the second reference point when compared to the accuracy of the ink image at the closest point In such circumstances, software modifications may be necessary to the image to accommodate for image distortions at locations on the golf ball located near the second reference point In one embodiment, the second reference point is about In another embodiment, a zone of distortion has been identified as a region of the ball that has significant image distortion due to the distance of the ball being further from the printer head In one example, the upper zone of distortion border and lower zone of distortion border begins after an upper boundary distance and lower boundary distance , respectively, as measured along the vertical rotation axis away from a center plane The center plane passes through the closest point and the center of the ball The upper zone of distortion begins after the upper boundary distance and continues until the upper most point of the ball.

The lower zone of distortion begins at the after the lower boundary distance and continues until the lower most point of the ball. In one embodiment, the upper boundary distance and lower boundary distance is 5 mm away from the center plane The intended printing image may need to be adjusted in the software programs utilized for printing for image portions located in the upper zone of distortion and lower zone of distortion In other embodiments, the lower boundary distance and upper boundary distance may be 6 mm, 7 mm, 8 mm, 9 mm, 10 mm, 11 mm, 12 mm, 13 mm, 14 mm, 15 mm, 16 mm, 17 mm, 18 mm, 19 mm, or 20 mm away from the center plane In simple terms, if an intended image design is superimposed on a printed image, areas of distortion can be identified.

The ball rotation rate of the golf ball as it rotates about the vertical rotation axis is between 1 to 7 revolutions per second rps or between 60 revolutions per minute to revolutions per minute rpm. In one embodiment, the revolutions per second can be 2 to 3 rps or as low as between 0. In one embodiment, the ball rotation rate can vary between 1 rpm to rpm, between 10 rpm to rpm, between 50 rpm to rpm, 80 rpm to rpm, rpm to rpm.

The ball rotation rates defined herein are based on a ball circumference of about In one example, the ball diameter is 1. The print rate or scan rate is how quickly the printer head can print an image on a surface without seeing significant distortions in the image. In addition, the dispense rate is defined as the rate of ink being dispensed from the printer head In one embodiment, the volume of a single ink droplet is between 6 to picoliters, between 0 to picoliters, between 50 to picoliters between 6 to 42 picoliters, between 12 to 84 picoliters, between 40 to picoliters, or between 75 to picoliters.

The resolution of the printed area on the golf ball can vary between to dots per inch dpi , between dpi and dpi, between dpi and dpi, between dpi and dpi, between dpi and dpi, or between dpi and dpi. Is a beta ti ls golf ball usga legal The typical firing frequency of the printer heads can be between 6 to 12 kHz. In one embodiment, the print swathe width is between 1 mm to 25 mm, 3 mm to 20 mm, 4 mm to 15 mm, 5 mm to 10 mm, 25 mm to mm, between to mm, or between 60 to 80 mm.

In some embodiment, a plurality of printer heads are utilized for each color. For example, a black, red, and blue printed area would require at least three printer heads located in a serial arrangement so as to apply each color in successive stages of printing. The printer heads are capable of printing in at least five colors including cyan, magenta, yellow, black, and white.

It is possible to print in any number of colors beyond the CMYK inks depending on how many printer heads are available. After the first color is applied, the golf ball passes through a first ink curing station A before proceeding to the second printer head B at a second printer station to apply a second color.

After the second color is applied to the golf ball , the ball is cured at a second ink curing station B. The second ink curing station B can be a UV pinning operation where low power level UV light is applied or the second ink curing station can be a final curing station where a higher power level of UV light when compared to the UV pinning operation is applied to cure all the ink applied to the golf ball This process can be repeated for as many colors as required for printing a certain image.

In one embodiment, there are between 1 and 20 printer heads and between 1 and 20 curing stations. In some embodiments, there can be two or more printer heads per printer station applying at least two or more different colors on the golf ball simultaneously. As shown in FIG. The first printer head A prints at least a first image on the golf ball Additionally, a second printer head B can be connected in the manufacturing process to be located after the rotational printing station.

In another embodiment, the first printer head A may be located at a linear printing station and the second printer head B can be located at a rotational printing station. In yet another embodiment, the first printer head A and the second printer head B can both be rotational printing stations.

In yet another embodiment, the first printer head A and the second printer head B can both be linear printing stations and having a reorientation mechanism located between the first printer head A and the second printer head B to rotate the golf ball by about 90 degrees, or between 45 degrees and degrees along a horizontal axis that is perpendicular to the axis of rotation In yet another embodiment, the first printer head A may be located at a rotational printing station and a plurality of printer heads, such as at least two, three, four, or five or more subsequent printer heads may be located at linear printing stations.

In one embodiment, the digital encoder can rotate the golf ball by between forty-five degrees to about ninety degrees about the vertical axis of rotation between the first printer head A and the second printer head B in order to print four images on a golf ball at first distinct locations on the ball.  These four images can also be printed at linear printing stations. Additionally, the golf ball can be rotated along the horizontal axis in between printing stations A, B to allow for the rotation of the golf ball along a horizontal axis that is perpendicular to the vertical axis of rotation In FIG.

These four images can also be printed at linear printing stations. Additionally, the golf ball can be rotated along the horizontal axis in between printing stations A, B to allow for the rotation of the golf ball along a horizontal axis that is perpendicular to the vertical axis of rotation In FIG.

The speed at which balls are printed can be between 20 and balls per minute, or between and balls per minute. In one embodiment, each linear printing station will require at least four printing heads for each image printed at the station. However, at the rotational printing station, the four printing heads can be utilized to print multiple images. In one embodiment, the curing stations include a UV pinning operation having lamps with a power rating of between 0 and 20 watts or between 1.

In one embodiment, a UV pinning operation is used having lamps of a lower wattage than a final UV curing lamp. For example, the pinning lamps may have a power rating of 5 W or less while the final UV curing has a power rating of more than 5 W or 5 W to 15 W. In certain embodiments, photo initiators can be present in the ink to narrow the wavelength of light in which curing occurs and thereby reducing ambient light contamination during the curing process.

In one embodiment, the pinning lamps have an energy density that is less than the final curing lamps. In some embodiments, the printer head curved surface has a radius of about 0. The curved surface of the printer allows for the ink droplets to travel a more uniform distance between the golf ball and the printer head. A more uniform distance between the ink dispensing surface and the surface of the golf ball can result in more consistent and higher quality images.

The shaft has a shaft axis and a fluted section length The grip has a grip length A printer head is located adjacent to the shaft The printer head may be configured to be a single pass printer head or a multiple pass printer head. If a multiple pass printer head is utilized, all the parameters of printing and curing described in this application apply equally in each pass of the multiple pass printer application.

A multiple pass printer head needs to make multiple movements across an object to completely print a desired image or pattern. In one embodiment, the printer head prints a solid color, pattern, or image in the fluted section located within the fluted section length. In one embodiment, the printer head moves in a direction parallel to the surface of the shaft that is being printed where the printer head is angled by an angle between 0 and 10 degrees, 1 and 8 degrees, or 2 and 7 degrees relative to the shaft axis In another embodiment, the printer head moves parallel to the shaft axis In one embodiment, the printer head moves in a first direction toward the grip and second direction toward the club head In one embodiment, the printing of ink on the shaft is applied while the printer head is moving in the first direction only and the printer head is reset without printing while moving in the second direction In another embodiment, the printer head is moving in the second direction while the ink is applied to the shaft and reset without any printing while moving in the first direction In yet another embodiment, the printer head has a UV curing light connected to or located on the printer head so that the ink is pre-cured in a UV pinning operation after each application of ink is applied to the shaft The UV pinning lamp parameters can be identical to those described previously.

Flutes are indentations or recessed regions in the shaft that extend longitudinally along the shaft axis Each flute is relatively parallel with the adjacent flutes. In one embodiment, the number of flutes can be 1 to 20, 2 to 10, 3 to 7, or 4 to 6 located on the shaft The shaft can be metal, composite, or plastic. In one embodiment, only the flutes have ink applied to the surface while the unpainted regions are located between each of the printed flutes In one embodiment, the unprinted region located between the printed flutes has a surface area that is less than the printed flutes surface area.

In one embodiment, the unprinted region within the cross-sectional view has a first outer surface contour length measured two dimensionally as shown in the FIG. In determining where the unprinted region first outer contour length ends and the second outer contour length in the flutes begins when measuring the contour length, a transition point having a radius of 5 mm ore more can be the point of separation between unprinted region and flutes when trying to determine the first and second outer contour length.

In one embodiment, a first outer contour length divided by a second outer contour is a Contour Ratio. The Contour Ratio can be less than 1, between 0. In one embodiment, the fluted section length can be between 1 mm and mm, between 2 mm and mm, between 5 mm and mm, between 20 mm and mm or between 25 mm and mm. In one embodiment, the fluted section length can be shorter than the grip length In another embodiment, the fluted section length can be longer than the grip length In one embodiment, the ratio between the fluted section length and the grip length is between 0.

The printing can occur before the shaft of the putter is assembled and attached to the putter head The shaft can be placed on a flat bed roller and the shaft can be rolled in a direction perpendicular to the shaft axis as the printer head makes multiple passes to print swathes of ink within the flutes In one embodiment, the print swathes are the same width as the flute lengths.

In another embodiment, a single polyurethane or polyurea composition may be utilized rather than a first color-containing composition and a second color-containing composition as described above. In particular, a single color-containing polyurethane composition may be being used in combination with secondary application of either paint or ink for creating the circumferential stripes.

A wide white circumferential stripe is placed on the golf ball using one of the stamping processes outlined above. A second black circumferential stripe is applied centered on top of the white circumferential stripe using similar stamping processes. If having the base urethane color in place of the black stripe is preferred, during the white stripe stamping application a center portion of the stamping area could be left out to stamp two parallel white stripes during the same application.

A center black circumferential stripe can be applied using any of the stamping processes outlined above. The embodiments shown in FIGS. A series of clear coats, with or without additives, are applied to the golf ball for durability and to achieve a gloss finish.

Matte clear is also an option. The printed images can be either under or over the clear coat. In some embodiments, the circumferential stripes can be stamped or printed over the clear coat layer. The image, pole stamp, or pole marking ink may be UV curable compositions. La bete golf course map For example, the image ink may be a UV curable epoxy.

Alternatively, the image, pole stamp, or pole marking ink may be curable by another mechanism such as heat. A clear coat e. In one exemplary embodiment, a paint can be applied to the cover layer surface of any color suitable for alignment. The multi-color cover layers disclosed herein can be used on any golf ball.

In certain embodiments, the golf ball has a core and a cover layer surrounding the core. In certain embodiments, the golf ball has a core, at least one mantle layer, and a cover layer. The golf ball may be a two-piece ball, a three-piece ball, a four-piece ball, a five-piece ball, or a six-piece ball.

If the cover consists of two or more layers, only the outermost layer is designated the cover layer, and the remaining layers excluding the outermost layer are commonly designated intermediate layers as herein defined. The cover layer can be used with golf balls of any desired size. The preferred diameter of the golf balls is from about 1.

The more preferred diameter is from about 1. A diameter of from about 1. Oversize golf balls with diameters above about 1. Each of the mantle layers of the golf balls may have a thickness of less than 0. In certain embodiments the inner mantle may have a material Shore D hardness of 15 to 65, particularly 25 to 60, and more particularly 30 to The inner mantle may have a flexural modulus of 2 to 35, particularly 10 to 30, and more particularly 15 to 35, kpsi.

The intermediate mantle may have a flexural modulus of 10 to 50, particularly 25 to 50, and most particularly 25 to 40, kpsi, and a material Shore D hardness of 40 to 70, more particularly from 45 to 65, and most particularly from 50 to The outer mantle may have a material Shore D hardness of 55 to 75, particularly 58 to 70, and more particularly 60 to The outer mantle material may have a flexural modulus of 30 to 80, particularly 40 to 80, and most particularly 50 to 75, kpsi.

The core and mantle layer s may each include one or more of the following polymers. More particularly, the synthetic and natural rubber polymers may include the traditional rubber components used in golf ball applications including, both natural and synthetic rubbers, such as cis-1,4-polybutadiene, trans-1,4-polybutadiene, 1,2-polybutadiene, cis-polyisoprene, trans-polyisoprene, polychloroprene, polybutylene, styrene-butadiene rubber, styrene-butadiene-styrene block copolymer and partially and fully hydrogenated equivalents, styrene-isoprene-styrene block copolymer and partially and fully hydrogenated equivalents, nitrile rubber, silicone rubber, and polyurethane, as well as mixtures of these.

The polybutadiene component may be synthesized by using rare earth-based catalysts, nickel-based catalysts, or cobalt-based catalysts, conventionally used in this field. Polybutadiene obtained by using lanthanum rare earth-based catalysts usually employ a combination of a lanthanum rare earth atomic number of 57 to 71 -compound, but particularly preferred is a neodymium compound.

Examples of 1,2-polybutadienes having differing tacticity, all of which are suitable as unsaturated polymers for use in the presently disclosed compositions, are atactic 1,2-polybutadiene, isotactic 1,2-polybutadiene, and syndiotactic 1,2-polybutadiene. Syndiotactic 1,2-polybutadiene having crystallinity suitable for use as an unsaturated polymer in the presently disclosed compositions are polymerized from a 1,2-addition of butadiene.

Also, the 1,2-polybutadiene may have a mean molecular weight between about 10, and about ,, more preferably between about 50, and about ,, more preferably between about 80, and about ,, and most preferably between about 10, and about , Examples of olefinic thermoplastic elastomers include metallocene-catalyzed polyolefins, ethylene-octene copolymer, ethylene-butene copolymer, and ethylene-propylene copolymers all with or without controlled tacticity as well as blends of polyolefins having ethyl-propylene-non-conjugated diene terpolymer, rubber-based copolymer, and dynamically vulcanized rubber-based copolymer.

The non-rubber repeating units of the copolymer may be derived from any suitable monomers, including meth acrylate esters, such as methyl methacrylate and cyclohexylmethacrylate, and vinyl arylenes, such as styrene. Examples of randomly distributed styrenic polymers include paramethylstyrene-isobutylene isobutene copolymers developed by ExxonMobil Chemical Corporation and styrene-butadiene random copolymers developed by Chevron Phillips Chemical Corp.

Examples of copolyester thermoplastic elastomers include polyether ester block copolymers, polylactone ester block copolymers, and aliphatic and aromatic dicarboxylic acid copolymerized polyesters. Polyether ester block copolymers are copolymers comprising polyester hard segments polymerized from a dicarboxylic acid and a low molecular weight diol, and polyether soft segments polymerized from an alkylene glycol having 2 to 10 atoms.

Polylactone ester block copolymers are copolymers having polylactone chains instead of polyether as the soft segments discussed above for polyether ester block copolymers. Aliphatic and aromatic dicarboxylic copolymerized polyesters are copolymers of an acid component selected from aromatic dicarboxylic acids, such as terephthalic acid and isophthalic acid, and aliphatic acids having 2 to 10 carbon atoms with at least one diol component, selected from aliphatic and alicyclic diols having 2 to 10 carbon atoms.

Blends of aromatic polyester and aliphatic polyester also may be used for these. Chemicals of Seoul, South Korea. Examples of other thermoplastic elastomers suitable as additional polymer components include those having functional groups, such as carboxylic acid, maleic anhydride, glycidyl, norbornene, and hydroxyl functionalities.

An example of these includes a block polymer having at least one polymer block A comprising an aromatic vinyl compound and at least one polymer block B comprising a conjugated diene compound, and having a hydroxyl group at the terminal block copolymer, or its hydrogenated product.

Another example of a polymer for making any of the mantle layers or cover layer is blend of a polyamide which may be a polyamide as described above with a functional polymer modifier of the polyamide. Is a beta ti ls golf ball usga legal The functional polymer modifier of the polyamide can include copolymers or terpolymers having a glycidyl group, hydroxyl group, maleic anhydride group or carboxylic group, collectively referred to as functionalized polymers.

Examples of suitable glycidyl groups in copolymers or terpolymers in the polymeric modifier include esters and ethers of aliphatic glycidyl, such as allylglycidylether, vinylglycidylether, glycidyl maleate and itaconatem glycidyl acrylate and methacrylate, and also alicyclic glycidyl esters and ethers, such as 2-cyclohexeneglycidylether, cyclohexene-4,5 diglyxidylcarboxylate, cyclohexeneglycidyl carboxylate, 5-norboenenemethylglycidyl carboxylate, and endocis-bicyclo 2,2,1 heptene-2,3-diglycidyl dicarboxylate.

These polymers having a glycidyl group may comprise other monomers, such as esters of unsaturated carboxylic acid, for example, alkyl meth acrylates or vinyl esters of unsaturated carboxylic acids. Polymers having a glycidyl group can be obtained by copolymerization or graft polymerization with homopolymers or copolymers.

Additional examples of copolymers comprising epoxy monomers and which are suitable for use within the scope of the present invention include styrene-butadiene-styrene block copolymers in which the polybutadiene block contains epoxy group, and styrene-isoprene-styrene block copolymers in which the polyisoprene block contains epoxy.

Examples of polymers or terpolymers incorporating a maleic anhydride group suitable for use within the scope of the present invention include maleic anhydride-modified ethylene-propylene copolymers, maleic anhydride-modified ethylene-propylene-diene terpolymers, maleic anhydride-modified polyethylenes, maleic anhydride-modified polypropylenes, ethylene-ethylacrylate-maleic anhydride terpolymers, and maleic anhydride-indene-styrene-cumarone polymers.

Preferably the functional polymer component for blending with a polyamide is a maleic anhydride grafted polymers preferably maleic anhydride grafted polyolefins for example, Exxellor VA Styrenic block copolymers are copolymers of styrene with butadiene, isoprene, or a mixture of the two. The styrenic block copolymer can be a diblock or a triblock styrenic polymer.

Examples of such styrenic block copolymers are described in, for example, U. The styrenic block copolymer can have any known molecular weight for such polymers, and it can possess a linear, branched, star, dendrimeric or combination molecular structure. The styrenic block copolymer can be unmodified by functional groups, or it can be modified by hydroxyl group, carboxyl group, or other functional groups, either in its chain structure or at one or more terminus.

The styrenic block copolymer can be obtained using any common process for manufacture of such polymers. The styrenic block copolymers also may be hydrogenated using well-known methods to obtain a partially or fully saturated diene monomer block. For example, SEPTON HG is a triblock copolymer, which has polystyrene end blocks and a hydrogenated polyisoprene midblock and has hydroxyl groups at the end of the polystyrene blocks.

HG is commercially available from Kuraray America Inc. Houston, Texas. Additional other polymer components include polyalkenamers as described, for example, in USA1, which is incorporated herein by reference in its entirety. Examples of suitable polyalkenamer rubbers are polypentenamer rubber, polyheptenamer rubber, polyoctenamer rubber, polydecenamer rubber and polydodecenamer rubber.

For further details concerning polyalkenamer rubber, see Rubber Chem. Both of these polymers have a double bond at every eighth carbon atom in the ring. If a polyalkenamer rubber is present, the polyalkenamer rubber preferably contains from about 50 to about 99, preferably from about 60 to about 99, more preferably from about 65 to about 99, even more preferably from about 70 to about 90 percent of its double bonds in the trans-configuration.

The polyalkenamer rubber has a molecular weight as measured by GPC from about 10, to about ,, preferably from about 20, to about ,, more preferably from about 30, to about ,, even more preferably from about 50, to about , The polyalkenamer rubber has a degree of crystallization as measured by DSC secondary fusion from about 5 to about 70, preferably from about 6 to about 50, more preferably from about from 6.

More preferably, the polyalkenamer rubber is a polymer prepared by polymerization of cyclooctene to form a trans-polyoctenamer rubber as a mixture of linear and cyclic macromolecules. A specialty propylene elastomer includes a thermoplastic propylene-ethylene copolymer composed of a majority amount of propylene and a minority amount of ethylene.

These copolymers have at least partial crystallinity due to adjacent isotactic propylene units. Although not bound by any theory, it is believed that the crystalline segments are physical crosslinking sites at room temperature, and at high temperature i. Suitable specialty propylene elastomers include propylene-ethylene copolymers produced in the presence of a metallocene catalyst.

More specific examples of specialty propylene elastomers are illustrated below. Another example of an additional polymer component includes the thermoplastic polyurethanes, which are the reaction product of a diol or polyol and an isocyanate, with or without a chain extender. Isocyanates used for making the urethanes encompass diisocyanates and polyisocyanates.

Each isocyanate may be used either alone or in combination with one or more other isocyanates. These isocyanate mixtures can include triisocyanates, such as biuret of hexamethylene diisocyanate and triphenylmethane triisocyanate, and polyisocyanates, such as polymeric diphenylmethane diisocyanate. As stated above, the urethane also may incorporate chain extenders.

In what is known as a one-shot process, the three reactants, diisocyanate, polyol or polyamine, and optionally a chain extender or a curing agent, are combined in one step. Alternatively, a two-step process may occur in which the first step involves reacting the diisocyanate and the polyol in the case of polyurethane or the polyamine in the case of a polyurea to form a so-called prepolymer, to which can then be added either the chain extender or the curing agent.

Finally, in addition to discrete thermoplastic or thermoset materials, it also is possible to modify a thermoplastic polyurethane or polyurea composition by introducing materials in the composition that undergo subsequent curing after molding the thermoplastic to provide properties similar to those of a thermoset. For example, Kim in U. Also, Kim et al. The modified isocyanate preferably is selected from the group consisting of: isophorone diisocyanate IPDI -based uretdione-type crosslinker; a combination of a uretdione adduct of IPDI and a partially e-caprolactam-modified IPDI; a combination of isocyanate adducts modified by e-caprolactam and a carboxylic acid functional group; a caprolactam-modified Desmodur diisocyanate; a Desmodur diisocyanate having a 3,5-dimethyl pyrazole modified isocyanate; or mixtures of these.

Finally, Kim et al. The nitroso reaction product has a characteristic temperature at which it decomposes to regenerate the nitroso compound and diisocyanate or polyisocyanate. Thus, by judicious choice of the post-processing temperature, further crosslinking can be induced in the originally thermoplastic composition to provide thermoset-like properties.

Any isocyanate available to one of ordinary skill in the art is suitable for use according to the invention. Isocyanates for use with the present invention include, but are not limited to, aliphatic, cycloaliphatic, aromatic aliphatic, aromatic, any derivatives thereof, and combinations of these compounds having two or more isocyanate NCO groups per molecule.

In view of the advantages of injection molding versus the more complex casting process, under some circumstances it is advantageous to have formulations capable of curing as a thermoset but only within a specified temperature range above that of the typical injection molding process. This allows parts, such as golf ball cover layers, to be initially injection molded, followed by subsequent processing at higher temperatures and pressures to induce further crosslinking and curing, resulting in thermoset properties in the final part.

Such an initially injection moldable composition is thus called a post curable urethane or urea composition. In one exemplary embodiment, a post curable urethane or rea can be sued for the multi-color cover layer. If a post curable urethane composition is required, a modified or blocked diisocyanate which subsequently unblocks and induces further cross-linking post extrusion may be included in the diisocyanate starting material.

Modified isocyanates used for making the polyurethanes of the present invention generally are defined as chemical compounds containing isocyanate groups that are not reactive at room temperature, but that become reactive once they reach a characteristic temperature.

The resulting isocyanates can act as crosslinking agents or chain extenders to form crosslinked polyurethanes. The degree of crosslinking is governed by type and concentration of modified isocyanate presented in the composition. The modified isocyanate used in the composition preferably is selected, in part, to have a characteristic temperature sufficiently high such that the urethane in the composition will retain its thermoplastic behavior during initial processing such as injection molding.

If a characteristic temperature is too low, the composition crosslinks before processing is completed, leading to process difficulties. The modified isocyanate preferably is selected from isophorone diisocyanate IPDI -based uretdione-type crosslinker; a combination of a uretdione adduct of IPDI and a partially e-caprolactam-modified IPDI; a combination of isocyanate adducts modified by e-caprolactam and a carboxylic acid functional group; a caprolactam-modified Desmodur diisocyanate; a Desmodur diisocyanate having a 3,5-dimethyl pyrazole modified isocyanate; or mixtures of these.

These modified isocyanates may be used either alone or in combination. Such modified diisocyanates are described in more detail in U. As an alternative if a post curable polyurethane or polyurea composition is required, the diisocyanate may further comprise reaction product of a nitroso compound and a diisocyanate or a polyisocyanate.

The reaction product has a characteristic temperature at which it decomposes regenerating the nitroso compound and diisocyanate or polyisocyanate, which can, by judicious choice of the post processing temperature, in turn induce further crosslinking in the originally thermoplastic composition resulting in thermoset-like properties.

Alternatively, the premix can be melt-processed using an extruder, such as single screw, co-rotating twin screw, or counter-rotating twin screw extruder, to produce the reaction product. The mixing methods discussed above can be used together to melt-mix the three components to prepare the compositions of the present invention. Also, the components can be fed into an extruder simultaneously or sequentially.

Most preferably, Components A and B are melt-mixed together without Component C, with or without the premixing discussed above, to produce a melt-mixture of the two components. This mixture is melt-mixed to produce the reaction product. This two-step mixing can be performed in a single process, such as, for example, an extrusion process using a proper barrel length or screw configuration, along with a multiple feeding system.

In this case, Components A and B can be fed into the extruder through a main hopper to be melted and well-mixed while flowing downstream through the extruder. Then Component C can be fed into the extruder to react with the mixture of Components A and B between the feeding port for Component C and the die head of the extruder.

The final polymer composition then exits from the die. If desired, any extra steps of melt-mixing can be added to either approach of the method of the present invention to provide for improved mixing or completion of the reaction between Components A and C. Also, additional components discussed above can be incorporated either into a premix, or at any of the melt-mixing stages.

Alternatively, Components A, B, and C can be melt-mixed simultaneously to form in-situ a pseudo-crosslinked structure of Component A in the presence of Component B, either as a fully or semi-interpenetrating network. In certain examples, the dicarboxylic acid may be an aromatic dicarboxylic acid or a cycloaliphatic dicarboxylic acid.

In certain examples, the diamine may be an aromatic diamine or a cycloaliphatic diamine. The polyamide may be any homopolyamide or copolyamide. One example of a group of suitable polyamides is thermoplastic polyamide elastomers. Thermoplastic polyamide elastomers typically are copolymers of a polyamide and polyester or polyether.

For example, the thermoplastic polyamide elastomer can contain a polyamide Nylon 6, Nylon 66, Nylon 11, Nylon 12 and the like as a hard segment and a polyether or polyester as a soft segment. In one specific example, the thermoplastic polyamides are amorphous copolyamides based on polyamide PA One class of copolyamide elastomers are polyether amide elastomers.

Illustrative examples of polyether amide elastomers are those that result from the copolycondensation of polyamide blocks having reactive chain ends with polyether blocks having reactive chain ends, including: 1 polyamide blocks of diamine chain ends with polyoxyalkylene sequences of dicarboxylic chains; 2 polyamide blocks of dicarboxylic chain ends with polyoxyalkylene sequences of diamine chain ends obtained by cyanoethylation and hydrogenation of polyoxyalkylene alpha-omega dihydroxylated aliphatic sequences known as polyether diols; and 3 polyamide blocks of dicarboxylic chain ends with polyether diols, the products obtained, in this particular case, being polyetheresteramides.

More specifically, the polyamide elastomer can be prepared by polycondensation of the components i a diamine and a dicarboxylate, lactames or an amino dicarboxylic acid PA component , ii a polyoxyalkylene glycol such as polyoxyethylene glycol, polyoxy propylene glycol PG component and iii a dicarboxylic acid.

The polyamide blocks of dicarboxylic chain ends come, for example, from the condensation of alpha-omega aminocarboxylic acids of lactam or of carboxylic diacids and diamines in the presence of a carboxylic diacid which limits the chain length. The molecular weight of the polyamide sequences is preferably between about and 15,, and more preferably between about and 5, The molecular weight of the polyether sequences is preferably between about and 6,, and more preferably between about and 3, The amide block polyethers may also comprise randomly distributed units.

These polymers may be prepared by the simultaneous reaction of polyether and precursor of polyamide blocks. For example, the polyether diol may react with a lactam or alpha-omega amino acid and a diacid which limits the chain in the presence of water. Suitable amide block polyethers include those as disclosed in U. The polyether blocks may be along the polymer chain in the form of diols or diamines.

The polyether block comprises different units such as units which derive from ethylene glycol, propylene glycol, or tetramethylene glycol. The amide block polyether comprises at least one type of polyamide block and one type of polyether block. Mixing of two or more polymers with polyamide blocks and polyether blocks may also be used. The amide block polyether also can comprise any amide structure made from the method described on the above.

Preferably, the amide block polyether is such that it represents the major component in weight, i. One type of polyetherester elastomer is the family of Pebax, which are available from Elf-Atochem Company. Preferably, the choice can be made from among Pebax , , , , and Blends or combinations of Pebax , , , , and can also be prepared, as well.

The layer or core compositions can also incorporate one or more fillers. Such fillers are typically in a finely divided form, for example, in a size generally less than about 20 mesh, preferably less than about mesh U. Flock and fiber sizes should be small enough to facilitate processing. Filler particle size will depend upon desired effect, cost, ease of addition, and dusting considerations.

The appropriate amounts of filler required will vary depending on the application but typically can be readily determined without undue experimentation. The filler preferably is selected from the group consisting of precipitated hydrated silica, limestone, clay, talc, asbestos, barytes, glass fibers, aramid fibers, mica, calcium metasilicate, barium sulfate, zinc sulfide, lithopone, silicates, silicon carbide, diatomaceous earth, carbonates such as calcium or magnesium or barium carbonate, sulfates such as calcium or magnesium or barium sulfate, metals, including tungsten steel copper, cobalt or iron, metal alloys, tungsten carbide, metal oxides, metal stearates, and other particulate carbonaceous materials, and any and all combinations thereof.

Preferred examples of fillers include metal oxides, such as zinc oxide and magnesium oxide. In another preferred embodiment the filler comprises a continuous or non-continuous fiber. In another preferred embodiment the filler comprises one or more so called nanofillers, as described in U. Inorganic nanofiller material generally is made of clay, such as hydrotalcite, phyllosilicate, saponite, hectorite, beidellite, stevensite, vermiculite, halloysite, mica, montmorillonite, micafluoride, or octosilicate.

To facilitate incorporation of the nanofiller material into a polymer material, either in preparing nanocomposite materials or in preparing polymer-based golf ball compositions, the clay particles generally are coated or treated by a suitable compatibilizing agent. The compatibilizing agent allows for superior linkage between the inorganic and organic material, and it also can account for the hydrophilic nature of the inorganic nanofiller material and the possibly hydrophobic nature of the polymer.

Compatibilizing agents may exhibit a variety of different structures depending upon the nature of both the inorganic nanofiller material and the target matrix polymer. Non-limiting examples include hydroxy-, thiol-, amino-, epoxy-, carboxylic acid-, ester-, amide-, and siloxy-group containing compounds, oligomers or polymers.

The nanofiller materials can be incorporated into the polymer either by dispersion into the particular monomer or oligomer prior to polymerization, or by melt compounding of the particles into the matrix polymer. Arlington Heights, Illinois. As mentioned above, the nanofiller particles have an aggregate structure with the aggregates particle sizes in the micron range and above.

However, these aggregates have a stacked plate structure with the individual platelets being roughly 1 nanometer nm thick and to nm across. As a result, nanofillers have extremely high surface area, resulting in high reinforcement efficiency to the material at low loading levels of the particles.

The sub-micron-sized particles enhance the stiffness of the material, without increasing its weight or opacity and without reducing the material's low-temperature toughness. Nanofillers when added into a matrix polymer, can be mixed in three ways. In one type of mixing there is dispersion of the aggregate structures within the matrix polymer, but on mixing no interaction of the matrix polymer with the aggregate platelet structure occurs, and thus the stacked platelet structure is essentially maintained.

However, if the nanofiller material is selected correctly, the matrix polymer chains can penetrate into the aggregates and separate the platelets, and thus when viewed by transmission electron microscopy or x-ray diffraction, the aggregates of platelets are expanded. At this point the nanofiller is said to be substantially evenly dispersed within and reacted into the structure of the matrix polymer.

This level of expansion can occur to differing degrees. In some cases, further penetration of the matrix polymer chains into the aggregate structure separates the platelets, and leads to a complete breaking up of the platelet's stacked structure in the aggregate and thus when viewed by transmission electron microscopy TEM , the individual platelets are thoroughly mixed throughout the matrix polymer.

An exfoliated nanofiller has the platelets fully dispersed throughout the polymer matrix; the platelets may be dispersed unevenly but preferably are dispersed evenly. While not wishing to be limited to any theory, one possible explanation of the differing degrees of dispersion of such nanofillers within the matrix polymer structure is the effect of the compatibilizer surface coating on the interaction between the nanofiller platelet structure and the matrix polymer.

By careful selection of the nanofiller it is possible to vary the penetration of the matrix polymer into the platelet structure of the nanofiller on mixing. Thus, the degree of interaction and intrusion of the polymer matrix into the nanofiller controls the separation and dispersion of the individual platelets of the nanofiller within the polymer matrix.

If no compatibilizer is present on the surface of a filler such as a clay, or if the coating of the clay is attempted after its addition to the polymer matrix, then the penetration of the matrix polymer into the nanofiller is much less efficient, very little separation and no dispersion of the individual clay platelets occurs within the matrix polymer.

Physical properties of the polymer will change with the addition of nanofiller and the physical properties of the polymer are expected to improve even more as the nanofiller is dispersed into the polymer matrix to form a nanocomposite. Materials incorporating nanofiller materials can provide these property improvements at much lower densities than those incorporating conventional fillers.

Because use of nanocomposite materials with lower loadings of inorganic materials than conventional fillers provides the same properties, this use allows products to be lighter than those with conventional fillers, while maintaining those same properties. Nanocomposite materials are materials incorporating from about 0. Descriptions of particular nanocomposite materials and their manufacture can be found in U.

When nanocomposites are blended with other polymer systems, the nanocomposite may be considered a type of nanofiller concentrate. Preferably the nanofiller material is added to the polymeric composition in an amount of from about 0. If desired, the various polymer compositions used to prepare the golf balls can additionally contain other additives such as plasticizers, pigments, antioxidants, U.

Another particularly well-suited additive for use in the presently disclosed compositions includes compounds having the general formula:. These materials are more fully described in copending U. Provisional Patent Application No. Vanderbilt Co. In an especially preferred embodiment a nanofiller additive component in the golf ball is surface modified with a compatibilizing agent comprising the earlier described compounds having the general formula:.

A most preferred embodiment would be a filler comprising a nanofiller clay material surface modified with an amino acid including aminododecanoic acid. Such fillers are available from Nanonocor Co. Any crosslinking or curing system typically used for crosslinking may be used to crosslink the polymer s , if desired. Satisfactory crosslinking systems are based on sulfur-, peroxide-, azide-, maleimide- or resin-vulcanization agents, which may be used in conjunction with a vulcanization accelerator.

Examples of satisfactory crosslinking system components are zinc oxide, sulfur, organic peroxide, azo compounds, magnesium oxide, benzothiazole sulfenamide accelerator, benzothiazyl disulfide, phenolic curing resin, m-phenylene bis-maleimide, thiuram disulfide and dipentamethylene-thiuram hexasulfide.

More preferable cross-linking agents include peroxides, sulfur compounds, as well as mixtures of these. Non-limiting examples of suitable cross-linking agents include primary, secondary, or tertiary aliphatic or aromatic organic peroxides. Peroxides containing more than one peroxy group can be used, such as 2,5-dimethyl-2,5-di tert-butylperoxy hexane and 1,4-di- 2-tert-butyl peroxyisopropyl benzene.

Both symmetrical and asymmetrical peroxides can be used, for example, tert-butyl perbenzoate and tert-butyl cumyl peroxide. Peroxides incorporating carboxyl groups also are suitable. The decomposition of peroxides used as cross-linking agents in the disclosed compositions can be brought about by applying thermal energy, shear, irradiation e.

Both homolytically and heterolytically decomposed peroxide can be used. Non-limiting examples of suitable peroxides include: diacetyl peroxide; di-tert-butyl peroxide; dibenzoyl peroxide; dicumyl peroxide; 2,5-dimethyl-2,5-di benzoylperoxy hexane; 1,4-bis- t-butylperoxyisopropyl benzene; t-butylperoxybenzoate; 2,5-dimethyl-2,5-di- t-butylperoxy hexyne-3, such as Trigonox B, marketed by Akrochem Corp.

The cross-linking agents can be blended in total amounts of about 0. In a further embodiment, the cross-linking agents can be blended in total amounts of about 0. Besides the use of chemical cross-linking agents, exposure of the polymer-containing composition to radiation also can serve as a cross-linking agent.

Radiation can be applied to the polymer-containing composition by any known method, including using microwave or gamma radiation, or an electron beam device. Additives may also be used to improve radiation-induced crosslinking of the polymer-containing composition. The polymer containing-composition may also be blended with a co-cross-linking agent, which may be a metal salt of an unsaturated carboxylic acid.

Examples of these include zinc and magnesium salts of unsaturated fatty acids having 3 to 8 carbon atoms, such as acrylic acid, methacrylic acid, maleic acid, and fumaric acid, palmitic acid with the zinc salts of acrylic and methacrylic acid being most preferred.

The unsaturated carboxylic acid metal salt can be blended in any desired amount, but preferably in amounts of about 1 part to about parts by weight of the unsaturated carboxylic acid per parts by weight of the polymer-containing composition. Preferred organic sulfur compounds include pentachlorothiophenol, and dibenzamido diphenyldisulfide.

Examples of the metal salt of an organic sulfur compound include sodium, potassium, lithium, magnesium calcium, barium, cesium and zinc salts of the above-mentioned thiophenols and thiocarboxylic acids, with the zinc salt of pentachlorothiophenol being most preferred. More typically, such peptizers are heteroaryl or heterocyclic compounds having at least one heteroatom, and potentially plural heteroatoms, where the plural heteroatoms may be the same or different.

Such peptizers include peptizers such as an indole peptizer, a quinoline peptizer, an isoquinoline peptizer, a pyridine peptizer, purine peptizer, a pyrimidine peptizer, a diazine peptizer, a pyrazine peptizer, a triazine peptizer, a carbazole peptizer, or combinations of such peptizers.

Suitable peptizers also may include one or more additional functional groups, such as halogens, particularly chlorine; a sulfur-containing moiety exemplified by thiols, where the functional group is sulfhydrl —SH , thioethers, where the functional group is —SR, disulfides, R 1 S—SR 2 , etc. Such peptizers are more fully disclosed in copending U.

Application No. The peptizer, if employed in the golf balls, is present in an amount of from about 0. The polymer-containing composition can also comprise one or more accelerators of one or more classes. Accelerators can be of any class known for rubber processing including mercapto-, sulfenamide-, thiuram, dithiocarbamate, dithiocarbamyl-sulfenamide, xanthate, guanidine, amine, thiourea, and dithiophosphate accelerators.

A more complete list of commercially available accelerators is given in The Vanderbilt Rubber Handbook: 13 th Edition , R. Preferred accelerators include 2-mercaptobenzothiazole MBT and its salts. The polymer-containing composition can further incorporate from about 0.

More preferably, the ball composition can further incorporate from about 0. Referring to the drawing in FIG. In certain embodiments, the core of the balls may have a diameter of from 1. The core of the balls also may have a PGA compression of less than , preferably less than 90, and more preferably less than The PGA compression of the cores may range from 20 to 80, and preferably from 30 to The various core layer materials including the center may each exhibit a different material hardness.

The difference between the center hardness and that of the next adjacent layer, as well as the difference in hardness between the various core layers may be greater than 2, preferably greater than 5, most preferably greater than 10 units of Shore D. In one preferred embodiment, the hardness of the center and each sequential layer increases progressively outwards from the center to outer core layer.

In another preferred embodiment, the hardness of the center and each sequential layer decreases progressively inward from the outer core layer to the center. The core may be a solid core or a wound core. Any combination of the above-described property ranges for the core may be employed, but illustrative specific embodiments of the core include a diameter of 1. The core may be made from any of the polymers described above.

In certain embodiments, the core is made from polybutadiene. Again referring to the drawing in FIG. The mantle layer s of the golf balls may have a thickness of at least 0. The mantle layer thickness may range from 0. The mantle layer may have a material Shore D hardness of 45 to 75, preferably 50 to The mantle layer may be made from any suitable material, particularly those materials described herein.

In certain examples, the mantle layers may include a unimodal ionomer; a bimodal ionomer; a modified unimodal ionomer; a modified bimodal ionomer; a thermoset polyurethane; a polyester elastomer; a copolymer comprising at least one first co-monomer selected from butadiene, isoprene, ethylene or butylene and at least one second co-monomer selected from a meth acrylate or a vinyl arylene; a polyalkenamer; or any and all combinations or mixtures thereof.

The inner cover layer of the balls may have a thickness of less than or equal to 0. In certain embodiments, the inner cover layer may have a thickness of 0. The inner cover layer of the balls may have a material Shore D hardness from 10 to 65, preferably from 20 to In certain embodiments, the inner cover layer has a material Shore D hardness that is at least 3 units, preferably at least 8 units, more preferably at 15 units, most preferably at least 20 units, less than the material Shore D hardness of the outer cover layer.

The outer cover layer of the balls may have a thickness of at least 0. In certain embodiments, the outer cover layer may have a thickness of 0. The outer cover layer of the balls may have a material Shore D hardness from 30 to 70, preferably from 35 to The cover layers may be made from any suitable material, particularly those disclosed herein. In preferred embodiments, illustrative examples include a thermoplastic elastomer, a thermoset polyurethane, a thermoplastic polyurethane, a unimodal ionomer, a bimodal ionomer, a modified unimodal ionomer, a modified bimodal ionomer; or any and all combinations or mixtures thereof.

A coating layer may be disposed on, or adjacent to, the outer cover layer. Examples of such paints include vinyl acetate resin paints, vinyl acetate copolymer resin paints, EVA ethylene-vinyl acetate copolymer resin paints, acrylic ester co polymer resin paints, epoxy resin paints, thermosetting urethane resin paints, thermoplastic urethane resin paints, thermosetting acrylic resin paints, and unsaturated polyester resin paints.

The coating layer may be transparent, semi-transparent or translucent. In another embodiment, the COR of the golf balls may be greater than about 0. The polymer s , crosslinking agent s , filler s and the like can be mixed together with or without melting them. Dry blending equipment, such as a tumble mixer, V-blender, ribbon blender, or two-roll mill, can be used to mix the compositions.

The golf ball compositions can also be mixed using a mill, internal mixer such as a Banbury or Farrel continuous mixer, extruder or combinations of these, with or without application of thermal energy to produce melting. The various components can be mixed together with the cross-linking agents, or each additive can be added in an appropriate sequence to the milled unsaturated polymer.

In another method of manufacture the cross-linking agents and other components can be added to the unsaturated polymer as part of a concentrate using dry blending, roll milling, or melt mixing. The resulting mixture can be subjected to, for example, a compression or injection molding process, to obtain solid spheres for the core.

The polymer mixture is subjected to a molding cycle in which heat and pressure are applied while the mixture is confined within a mold. The cavity shape depends on the portion of the golf ball being formed. The compression and heat liberates free radicals by decomposing one or more peroxides, which initiate cross-linking.

The temperature and duration of the molding cycle are selected based upon the type of peroxide selected. The molding cycle may have a single step of molding the mixture at a single temperature for fixed time duration. After core formation, the golf ball cover and any mantle layers are typically positioned over the core using one of three methods: casting, injection molding, or compression molding.

The compatibilizing agent allows for superior linkage between the inorganic and organic material, and it also can account for the hydrophilic nature of the inorganic nanofiller material and the possibly hydrophobic nature of the polymer. Compatibilizing agents may exhibit a variety of different structures depending upon the nature of both the inorganic nanofiller material and the target matrix polymer.

Non-limiting examples include hydroxy-, thiol-, amino-, epoxy-, carboxylic acid-, ester-, amide-, and siloxy-group containing compounds, oligomers or polymers. The nanofiller materials can be incorporated into the polymer either by dispersion into the particular monomer or oligomer prior to polymerization, or by melt compounding of the particles into the matrix polymer.

Arlington Heights, Ill. Nanofillers when added into a matrix polymer, such as the polyalkenamer rubber, can be mixed using any suitable method. In one type of mixing there is dispersion of the aggregate structures within the matrix polymer, but on mixing no interaction of the matrix polymer with the aggregate platelet structure occurs, and thus the stacked platelet structure is essentially maintained.

However, if the nanofiller material is selected correctly, the matrix polymer chains can penetrate into the aggregates and separate the platelets, and thus when viewed by transmission electron microscopy or x-ray diffraction, the aggregates of platelets are expanded. At this point the nanofiller is said to be substantially evenly dispersed within and reacted into the structure of the matrix polymer.

This level of expansion can occur to differing degrees. In some circumstances, further penetration of the matrix polymer chains into the aggregate structure separates the platelets, and leads to a complete disruption of the platelet's stacked structure in the aggregate. Thus, when viewed by transmission electron microscopy TEM , the individual platelets are thoroughly mixed throughout the matrix polymer.

An exfoliated nanofiller has the platelets fully dispersed throughout the polymer matrix; the platelets may be dispersed unevenly but preferably are dispersed evenly. While not wishing to be limited to any theory, one possible explanation of the differing degrees of dispersion of such nanofillers within the matrix polymer structure is the effect of the compatibilizer surface coating on the interaction between the nanofiller platelet structure and the matrix polymer.

By careful selection of the nanofiller it is possible to vary the penetration of the matrix polymer into the platelet structure of the nanofiller on mixing. Thus, the degree of interaction and intrusion of the polymer matrix into the nanofiller controls the separation and dispersion of the individual platelets of the nanofiller within the polymer matrix.

If no compatibilizer is present on the surface of a filler such as a clay, or if the coating of the clay is attempted after its addition to the polymer matrix, then the penetration of the matrix polymer into the nanofiller is much less efficient, very little separation and no dispersion of the individual clay platelets occurs within the matrix polymer.

Physical properties of the polymer will change with the addition of nanofiller. The physical properties of the polymer are expected to improve even more as the nanofiller is dispersed into the polymer matrix to form a nanocomposite. Materials incorporating nanofiller materials can provide these property improvements at much lower densities than those incorporating conventional fillers.

Using nanocomposite materials with lower inorganic materials loadings than conventional fillers provides the same properties, and this allows products comprising nanocomposite fillers to be lighter than those with conventional fillers, while maintaining those same properties. Descriptions of particular nanocomposite materials and their manufacture can be found in U.

When nanocomposites are blended with other polymer systems, the nanocomposite may be considered a type of nanofiller concentrate. For the polyalkenamers, the nanofiller material is added in an amount up to at least about 20 weight percent, from about 0.

If desired, the various polymer compositions used to prepare the golf balls of the present invention can additionally contain other conventional additives such as plasticizers, pigments, antioxidants, U. Another particularly well-suited additive for use in the compositions of the present invention includes compounds having the general formula. These materials are more fully described in copending U.

In an especially preferred embodiment a nanofiller additive component in the golf ball of the present invention is surface modified with a compatibilizing agent comprising the earlier described compounds having the general formula. A most preferred embodiment would be a filler comprising a nanofiller clay material surface modified with an amino acid including aminododecanoic acid.

Such fillers are available from Nanonocor Co. The filler can be blended in variable effective amounts, such as amounts of greater than 0 to at least about 80 parts, and more typically from about 10 parts to about 80 parts, by weight per parts by weight of the base rubber. If desired, the rubber composition can additionally contain effective amounts of a plasticizer, an antioxidant, and any other additives generally used to make golf balls.

An amide is any organic compound containing the group —CONR 2 , where R is hydrogen; an aliphatic group, such as an alkyl group, an alkenyl group, or an alkynyl group; an aromatic group; and combinations thereof. Amides useful for the present invention may be a primary amide, a secondary amide, or a tertiary amide, and combinations thereof, i.

For example, if the first amide is a primary amide, the second amide moiety may be secondary or tertiary. The amide may be saturated or unsaturated. Moreover, unsaturated amides may have more than one site of unsaturation, including aromatic amides. Alkene amides may have a cis double bond or a trans double bond.

For compounds having plural sites of unsaturation, such double bonds can be all cis, all trans, or any combination of cis and trans double bonds. Certain compounds perform better as polymer modifier if the olefin is entirely or predominantly cis, or entirely or predominantly trans. Moreover, the position of the double bond in the compound may affect the compound's usefulness for modifying polymer compositions.

Fatty acid amides are a particularly useful genus of amides for use with the present invention. Fatty acids are any of a class of aliphatic monocarboxylic acids that form part of a lipid molecule and can be derived from fat by hydrolysis; fatty acids are simple molecules built around a series of carbon atoms linked together in a chain, typically a chain having from about 12 to about 22 carbon atoms.

Suitable amide polymer composition modifiers can include a functional group or groups other than the amide functionality. For example and without limitation, amide polymer modifiers also can include additional functional groups such as hydroxyl, sulthydryl, halides, glycidyl, carbonyl, carboxyl, anhydryl, ether, epoxide, amine, etc.

The polymer compositions of the present invention include amounts of the amide modifying agent effective to modify the compositions as desired. For example, amide modifiers can be used to provide more desirable rheological properties relative to non-modified polymeric compositions, more desirable mechanical properties relative to non-modified polymeric compositions, and combinations of rheological and mechanical properties.

By way of example, it was surprising to find that useful polymeric compositions modified with a suitable monomeric amide, or amides, could be made such that the rheological properties, for example the melt flow index MFI , could be advantageously modified. At the same time, mechanical properties, such as hardness, flexural modulus and COR, could be substantially maintained, and for some formulations improved, relative to the same composition without the monomeric amide, or amides.

By way of example and without limitation, it currently is believed that amide modifiers can be added in amounts ranging from about 0. Golf balls within the scope of the present invention also can include, in suitable amounts, one or more additional ingredients generally employed in golf ball compositions. Agents provided to achieve specific functions, such as additives and stabilizers, can be present.

Exemplary suitable ingredients include colorants, antioxidants, colorants, dispersants, mold releasing agents, processing aids, fillers, or any and all combinations thereof. Although not required, UV stabilizers, or photo stabilizers, such as substituted hydroxphenyl benzotriazoles, may be utilized in the present invention to enhance the UV stability of the final compositions.

Typically, the golf ball core is made by mixing together the various components and other additives with or without melting them. Dry blending equipment, such as a tumble mixer, V-blender, ribbon blender, or two-roll mill, can be used to mix the compositions. The golf ball compositions also can be mixed using a mill, internal mixer such as a Banbury or Farrel continuous mixer, extruder or combinations of these, with or without application of thermal energy to produce melting.

The various core components can be mixed together with the cross-linking agents, or each additive can be added in an appropriate sequence to the milled unsaturated polymer. In another method of manufacture the cross-linking agents and other components can be added to the unsaturated polymer as part of a concentrate using dry blending, roll milling, or melt mixing.

If radiation is a cross-linking agent, then the mixture comprising the unsaturated polymer and other additives can be irradiated following mixing, during forming into a part such as the core of a ball, or after forming. The resulting mixture can be subjected to, for example, a compression or injection molding process, to obtain solid spheres for the core.

The polymer mixture is subjected to a molding cycle in which heat and pressure are applied while the mixture is confined within a mold. The cavity shape depends on the portion of the golf ball being formed. The compression and heat liberates free radicals by decomposing one or more peroxides, which initiate cross-linking. The temperature and duration of the molding cycle are selected based upon the type of peroxide and peptizer selected.

The molding cycle may have a single step of molding the mixture at a single temperature for fixed time duration. The various core components also may be combined to form a golf ball by an injection molding process, which is also well known to one of ordinary skill in the art.

Although the curing time depends on the various materials selected, those of ordinary skill in the art will be readily able to adjust the curing time upward or downward based on the particular materials used and the discussion herein. The cover formulations can be injection molded around the cores to produce golf balls of the required diameter.

Alternatively, the cover layers also may be formed around the core by first forming half shells by injection molding followed by compression molding the half shells about the core to form the final ball. Covers also may be formed around the cores using compression molding.

Cover materials for compression molding also may be extruded or blended resins or castable resins. In the case of the reduced-yellowing thermoset of the present invention casting is a most preferred method for making desired articles, such as golf balls. Referring to the drawing in FIG.

The core of the two-piece golf balls of the present invention has a diameter of from about 0. The core of the two-piece golf balls of the present invention has a PGA compression of from about 10 to about , preferably from about 35 to about 90, more preferably from about 40 to about The cover of the two-piece golf balls of the present invention has a thickness of from about 0. In addition, the cover of the two-piece golf balls of the present invention has a hardness of from about 25 to about 80, more preferably from about 30 to about 70, even more preferably from about 40 to about 60 Shore D.

The two-piece golf ball of the present invention has a PGA ball compression greater than about 30, preferably greater than 40, more preferably greater than about 50, most preferably greater than about Referring to FIG. The core of the three-piece golf balls of the present invention has a diameter of from about 0.

The core of the three-piece golf balls of the present invention has a PGA compression of from about 10 to about , preferably from about 35 to about 90, more preferably from about 40 to about The cover of the three-piece golf balls of the present invention has a thickness of from about 0.

The cover of the three-piece golf balls of the present invention also has a hardness of from about 25 to about 80, more preferably from about 30 to about 70, even more preferably from about 40 to about 60 Shore D. The three-piece golf balls of the present invention has a PGA ball compression greater than about 30, preferably greater than 40, more preferably greater than about 50, most preferably greater than about The core of the golf balls of the present invention having two or more intermediate layers has a diameter of from about 0.

The core the golf balls of the present invention having two or more intermediate layers has a PGA compression of from about 10 to about , preferably from about 35 to about 90, more preferably from about 40 to about The core the golf balls of the present invention having two or more intermediate layers also may comprise a center and one or more core layers disposed around the center.

These core layers may be made from the same rubber as used in the center portion, or may be a different thermoplastic elastomer. The various core layers including the center may each exhibit a different hardness. The difference between the center hardness and that of the next adjacent layer, as well as the difference in hardness between the various core layers is greater than 2, preferably greater than 5, most preferably greater than 10 units of Shore D.

In one preferred embodiment, the hardness of the center and each sequential layer increases progressively outwards from the center to outer core layer. In another preferred embodiment, the hardness of the center and each sequential layer decreases progressively inwards from the outer core layer to the center.

The intermediate layers of the golf balls of the present invention having two or more intermediate layers has a thickness of about 0. The intermediate layers of the golf balls of the present invention having two or more intermediate layers also has a hardness greater than about 25, preferably greater than about 30, more preferably greater than about 40, and most preferably greater than about 50, Shore D units as measured on the ball.

The intermediate layers of the golf balls of the present invention having two or more intermediate layers also has a flexural modulus from about 5 to about , preferably from about 15 to about , more preferably from about 20 to about , still more preferably from about 25 to about , and most preferably from about 30 to about kpsi.

The cover layer of the golf balls of the present invention having two or more intermediate layers has a thickness of about 0. The cover layer of the golf balls of the present invention having two or more intermediate layers also has a hardness from about 40 to about 70, preferably from about 45 to about 70 or about 50 to about 70, more preferably from 47 to about 68 or about 45 to about 70, and most preferably from about 50 to about 65 Shore D as measured on the ball.

The COR of the two-, three- or multi-piece golf balls of the present invention is greater than about 0. The COR of the two-, three- or multi-piece golf balls of the present invention is also greater than about 0. The following examples are provided to illustrate certain features of working embodiments of the disclosed invention.

A person of ordinary skill in the art will appreciate that the invention is not limited to those features exemplified by these working embodiments. Shear Cut Resistance was measured using a swing robot and a 56 degree wedge that generates golf ball cover damage when struck aggressively. Prior to every impact, the club face is cleaned and sprayed with water.

The water acts as a lubricant and causes the balls to slide up the club face. As the ball slides up the face, the club grooves damage the ball. The robot was setup to generate a level of damage on a control ball of approximately 2. Once setup, test groups are hit with the same setup conditions. Golf balls with shear scores above 3 are considered less durable. PGA compression, C.

The sphere to be tested is forced a distance of 0. If the spring, in turn, compresses 0. Thus more compressible, softer materials will have lower Atti gauge values than harder, less compressible materials. The value is taken shortly after applying the force and within at least 5 secs if possible. Compression measured with this instrument is also referred to as PGA compression.

The approximate relationship that exists between Atti or PGA compression and Riehle compression can be expressed as:. Thus, a Riehle compression of would be the same as an Atti compression of The coefficient of restitution is the ratio of the relative velocity between two objects after direct impact to the relative velocity before impact.

As a result, the COR can vary from 0 to 1, with 1 being equivalent to a completely elastic collision and 0 being equivalent to a completely inelastic collision. Since a ball's COR directly influences the ball's initial velocity after club collision and travel distance, golf ball manufacturers are interested in this characteristic for designing and testing golf balls.

One conventional technique for measuring COR uses a golf ball or golf ball subassembly, air cannon, and a stationary steel plate. The steel plate provides an impact surface weighing about pounds or about 45 kilograms. A pair of ballistic light screens, which measure ball velocity, are spaced apart and located between the air cannon and the steel plate.

As the ball travels toward the steel plate, it activates each light screen so that the time at each light screen is measured. This provides an incoming time period proportional to the ball's incoming velocity. The ball impacts the steel plate and rebounds through the light screens, which again measure the time period required to transit between the light screens.

This provides an outgoing transit time period proportional to the ball's outgoing velocity. The COR depends on the golf ball construction as well as the chemical composition of the various layers. This example provides a comparison of ball physicals using inventive and comparative urethane covers formulations. All the formulations were mixed on a Labtech 2-roll mill using no additional heat.

The cores, having a diameter of 1. The inner-mantled cores were generated based on polyalkenamer-based material Vestenamer from Degussa using a curing agent consisting of a peroxide mixture with the additional components of zinc diacrylate, zinc oxide and zinc pentachlorothiophenol which was injection molded on the polybutadiene cores.

The inner-mantled cores, having a diameter of 1. The outer-mantled cores, having a diameter of 1. Two different urethane cover compositions having different curative mixtures were tested. In both cases, a urethane dispenser was used for proper mixing of two curatives and obtaining accurate weight of curative mixture.

The FlackTek high speed mixer was used for uniform mixing of prepolymer and curative mixture, and then the mixture was poured into the cavities for molding. The balls were then painted with two coats of a white pigmented paint supplied by RedSpot and containing a standard UV protection package. No clear coat was applied. The properties of the resulting balls are summarized in Table 1.

These data show that substitution of the Dyhard curative for the Ethacure results in no loss in Shear Cut resistance or ball COR for the same cover thickness and ball core and mantle s construction. This example concerns QUV experiments conducted on unpainted specimens. In this example, E was replaced with the dicyandiamide, Dyhard Degussa and adjusted mixing ratio to have approximately same gel time as the current curative mixture.

A urethane dispenser was used for proper mixing of two curatives and obtaining accurate weight of curative mixture. The FlackTek high speed mixer was used for uniform mixing of prepolymer and curative mixture, and then the mixture was poured into a mold to form an approximately 2 inches square specimen of thickness 0.